TecTonic Night Summit is an immersive, collaborative celebration of innovation and community, bringing people together through evening gatherings alongside business conferences and fringe events across Scotland.

Blending the energy of a live community gathering with the insight and business showcase elements of a conference, TecTonic events are an inclusive, dynamic showcase of connectivity and creativity within Scotland’s digital business landscape and startup ecosystem.

The name reflects the movement, intersection, and constant evolution of ideas, innovation, relationships, and collaboration across sectors, industries, and enterprise.

For each event, we draw together a new team of established and emerging Community Leaders to ensure fresh ideas and opportunities each year.

Key to the vision of the project is promoting a positive, united front of business support organisations and community groups, not just to showcase the incredible ecosystem we have, but also to create real opportunities for collaboration and cross-pollination between networks.

Jackie Sanderson and Elaine Sneddon of Interface will be attending this event.

Re-imagining high-performance homes running entirely on renewable energy and being completely self-efficient protecting their occupiers for decades.

Background

Kionnali Living Systems is a startup based in Aberdeenshire created by co-founders Avriel Skolnick and Corrin Fox whose backgrounds in science and engineering and experience in construction and manufacturing has enabled them to design and build LightForm, a prototype home utilising regenerative and resilient building technologies and integrated systems.

LightForm is a modular off-site manufactured home, featuring a unique home climate control system which generates all the heat a house needs, using renewable inputs, distributed recovery and local storage. Inputs include solar thermal collectors, air source heat pump powered by local renewables, and a clean burning biomass back up.

The Journey

Kionnali Living Systems is working to reimagine and build systems that take care of basic needs, from shelter, to energy, to food and water, locally and regeneratively and combine those systems into a modular home that deploys anywhere in minutes and provides everything needed to live, sustainably, on or off grid.

Kionnali was keen to collaborate on several areas including system architecture, materials study and thermal analysis. Initially referred by Business Gateway, the first collaboration instigated by Interface involved a PhD student with the National Environmental Research Council (NERC) and the University of Edinburgh who looked at how a structure with low compaction, no permanent foundation, combined with the introduction of carbon rich compost and clean water, would affect the microbiome of soil. The research found that Kionnali’s adaptable foundation and lightweight construction could significantly reduce impact from housing on compaction and soil biodiversity.

Taking cognisance of Scotland’s long-term climate change targets and the Scottish Government’s vision that by 2045 homes and buildings will be warmer, greener, and more efficient with renewable energy playing a significant part, Kionnali wanted to test their net-zero energy system concept for the development of self-sustained, net-zero energy buildings suitable for rural and farming communities.

Gillian Hambley, Business Engagement Executive at Interface connected Kionnali with Professor Alireza Maheri of the Centre of Energy Transition at Aberdeen University to perform a feasibility study to verify the Kionnali Net-zero Energy System concept and also evaluate the performance of Kionnali’s innovative technologies (low cost thermal storage system and biomass backup generator) in the context of a net-zero energy system integrated with renewable components (wind, PV, solar thermal) and storage systems.

Funded by an SFC Innovation Voucher the feasibility study conducted by Professor Alireza Maheri found that the Kionnali system can be 100% self-sustaining in any climate, with an 80% reduction in lifetime system cost and negative carbon emissions.

Through the project the company were able to confirm assumptions and develop new design spaces with multifactor optimisation. With the help of a SMART Scotland Grant which funded two full-time positions, the project led on to the development of a full-scale demonstration model.

Interface have continued to support Kionnali connecting them into the Advanced Materials Research Lab at the University of Strathclyde to develop a unique high efficiency, light weight, insulated, modular building panel.

The Benefits

Company

- Development of a modular home that deploys anywhere in minutes and can provide everything to sustain life, on or off grid.

- It is designed to adapt to weather patterns, lifestyle changes, and protect its inhabitants during and after a disaster.

- University expertise has helped prove and accelerate Kionnali’s concept and make their ambition to develop and build systems that take care of basic needs, from shelter, to energy, to food and water, and build sustainable, regenerative communities one step closer.

- Third party feasibility input provided crucial validation data points to propel further growth, from hiring to fundraising and sales.

Academic

- Provided the opportunity to continue research into distributed hybrid renewable energy systems and their impact on a just energy transition.

- Working on this project also provided a valuable opportunity for the further development of MOHRES, a specialised software tool designed to create stakeholders-in-the-loop net-zero energy solutions. MOHRES remains the only tool of its kind, and this collaboration has contributed to its continued refinement through the application to another real-life energy transition challenge.

The Next Steps

- Kionnali are ambitious and are aiming to reimagine the systems that sustain humanity and improve people’s lives with tangible, concrete solutions.

- They plan to grow their team to 15-20 creative doers. In 2025 they are launching three product lines of building technologies based on the Interface funded R&D: FireFly for small spaces, LightForm for residential systems, and LifeBlocks for organisations and disaster relief.

- Over the next 5-8 years the plan is to scale up to full production of the world’s most accessible, sustainable, smart living systems and expand to North America and Europe.

- Active discussions are ongoing with SRUC looking at an “organic waste management system” as an alternative to standard waste toilets that are easy to use, clean and produce sterilised soil. Kionnali will manufacture the composter but would like to collaborate with an academic partner to fully understand the quality of soil and water output from the system, considering soil composition, microbial makeup, and presence of chemicals. They plan to access the Advanced Innovation Voucher to power this work.

- Kionnali’s R&D journey continues at full speed and Interface have continued supporting with further funding applications and opportunities.

A one-day event for academics from the Universities of Edinburgh, Glasgow, Heriot-Watt, St Andrews, and Strathclyde. Hear impact success stories, find a collaboration partner from another Scottish university, and access funds for impact collaborations.

The festival will be held on 4 September 2024 at COSLA, Edinburgh Haymarket and will support you to:

- find out more about the opportunities, funding and training available to you to create impact from your research

- become a future impact leader

- network with like-minded researchers from five Scottish universities with EPSRC Impact Acceleration Accounts (IAAs)

Interface will be exhibiting at the festival please come along and say hello!

Back as the headline event of Glasgow Tech Week, Glasgow Tech Fest is a must-attend event for the tech, digital, and creative communities in Glasgow and beyond. Glasgow Tech Fest will bring together visionary founders, seasoned leaders, insightful investors, ecosystem champions, and experts to connect, network, and share ideas and learnings in a day of keynotes, panels, and fireside chats.

Learn from industry experts and gain practical knowledge with this year’s themes:

- Investing in the future

- Developing inclusive and collaborative ecosystems

- Scale and Growth

- Entrepreneurial journeys

- Breaking barriers

Opening keynote launching Glasgow Tech Fest is the incredible Dame Dr Maggie Aderin-Pocock from BBC’s The Sky at Night! Stay tuned as more additions to the agenda are announced, guaranteed to be the ultimate tech event in Scotland!

Hosted by the Department of Design, Manufacturing and Engineering Management (DMEM), this conference event showcases the innovative processes and outcomes from over 40 collaborative student team projects through a series of presentations.

As well as providing a platform for our students’ industry-related output, academics will highlight opportunities and mechanisms for industry to work collaboratively with us in the future.

Registration will take place from 08.45 and the event will close at 14.30.

Who should attend?

- Industrialists collaborating in DMEM industrial projects.

- Industrialists interested in finding out more about DMEM and collaborative opportunities.

- Interface and knowledge exchange professionals.

- Academic staff in the areas of design, manufacture and engineering management.

- Senior undergraduate and postgraduate students.

Danu Robotics is developing a revolutionary robotic waste sorting system to help the waste management industry significantly increase their productivity, prevent valuable resources going into landfill, boost the circular economy and clean up the environment.

Background

The world generates 3 billion tonnes of domestic solid waste annually, less than 10% of it is recycled. Worldwide, recycling sites require human intervention to pick out contaminants, which can pose health risks and is extremely inefficient.

Xiaoyan Ma founder of Edinburgh-based, clean tech company Danu Robotics, has combined her expertise in high performance computing (HPC) with her passion for the environment to revolutionise the efficiency of the recycling sector by developing an AI-powered, robotic sorting system.

She explained: “I have been a committed environmentalist since I was a teenager and always recycled my household waste, but I’d never thought about where it ended up. So, a couple of years ago, while I was studying, I decided to look into the whole process, and I was shocked at how inefficient it was.”

The Challenge

As a team of one, Xiaoyan needed help in identifying additional resources to support the development of the robotic solution. She required both experts in robotics and hardware development. She also called for help with software development and computer vision expertise. Experts in advanced data analytics and image recognition capability, would help develop a more accurate machine learning algorithm and object classification to enable the robotic system to differentiate between recyclable materials and general waste.

Following an introduction from John Hill, her student enterprise advisor at Edinburgh Innovations, Interface made several connections to different academic teams to support Danu Robotics on their journey of development.

The Solution

Interface connected Danu Robotics into the Design Manufacturing & Engineering Management (DMEM) department, at the University of Strathclyde. The DMEM students undertook a six-month project researching and developing the robotic picker equipped with a camera to identify objects and an appropriate algorithm to instruct the picker to pick out the recyclables and place them in a designated area. The robotic picker needed to meet predefined performance requirements, and in addition, the solution had to be durable, recyclable/sustainable, affordable, portable and re-programmable. Several options were considered to design robotic pickers that were fit for purpose ranging from, a custom solution where the robotic picker uses a suction and release mechanism rather than grab and release, to the modification of an off-the-shelf robot arm/picker to the combination of hard robot and soft robot.

In conjunction to this project, Interface also connected Danu Robotics into EPCC at the University of Edinburgh to develop software for identification and classification of objects and to define suitable hardware, including sensors and cameras, for the robotic picker.

The software development phase required development of a machine learning algorithm that takes image data and sensor data to differentiate recyclables from the general waste. The company had to build up a waste image database to help the system identify contaminants, the collection of the image data was supported by Glasgow City Council. Each item in this visual database was then labelled by a specialist data processing company and the updated database used to ‘train’ the machine learning algorithm to identify what can and cannot be recycled.

With initial system training complete, the software required further development to direct the robotic sorting system to remove contaminants from a moving conveyor belt as efficiently and effectively as possible. Working with EPCC’s Cirrus supercomputer resources, accelerated the development of the project, with two months of lab tests to integrate the software with the robotic hardware, followed by a three-month trial of the prototype system at Glasgow City Council’s recycling centre.

The initial collaboration with EPCC was funded by a SFC Innovation Voucher, then EU Horizon 2020 (H2020) funding which in turn helped leverage £70K in a SMART Scotland grant. They have recently secured SFC Advanced Innovation Voucher funding to continue development work with EPCC.

Other opportunities which Interface have been instrumental in assisting Danu Robotics with include:

- An MSc project for a design engineering student from Heriot Watt University interested in robotic design and kinematics to design a robotic arm that can sort waste items quickly and lift loads of up to 20kg while the entire arm assembly is moving at high speeds. An optimal design needed to consider the harsh dirty and dusty operating environment and the high speeds that the assembly needed to work in. The project provided an opportunity to produce an innovative and challenging piece of academic research, but also engagement in industrial research and product development.

- Another MSc opportunity with DMEM students at the University of Strathclyde involved the development of a control system for the waste sorting robot. Students interested in control systems, kinematics, and industrial design worked to identify a closed loop control system best suited for application in a heavy industrial robotic waste sorting system.

- A further project is underway with Design Engineering students at Heriot Watt University looking at the design and development of prototype of a new emergency stop system which needs to be designed to bring the mass to a stop in a safe manner. The robotic system uses a belt drive system driven by an industrial servo motor with no service break and currently relies on the frictional losses present to come to a stop in case of an emergency or loss of motor torque.

The Benefits

- The development of a revolutionary robotic system for the recycling and waste management industry to significantly increase recycling efficiency;

- Danu Robotics’ prototype can work at 40 picks per minute versus trained human operators that work around 10-20 picks per minute.

- It can reduce the contamination rate from current level of 50%, to 10% to below 1% while saving on operating costs ranging from 30% to 100%.

- The technology can be used by any recycling facility worldwide regardless of its size, its current technology or location. It can support recycling activities in both developed countries and developing nations.

- Danu Robotics’ efforts are paying off with several large European recycling companies showing interest in the product.

- Since inception in 2020 Danu Robotics has grown from 1 to 10 employees and has raised £275K from Sustainable Ventures and Old College Capital, £160K Smart funding, £75K EDGE Funding, £43K in support from Higgs Business Incubation Centre and £20K from SFC innovation voucher scheme.

- In September 2023, Danu Robotics joined the prestigious Octopus Ventures Springboard programme and CEO Xiaoyan Ma gave a keynote at the Carbon13 conference.

Overview

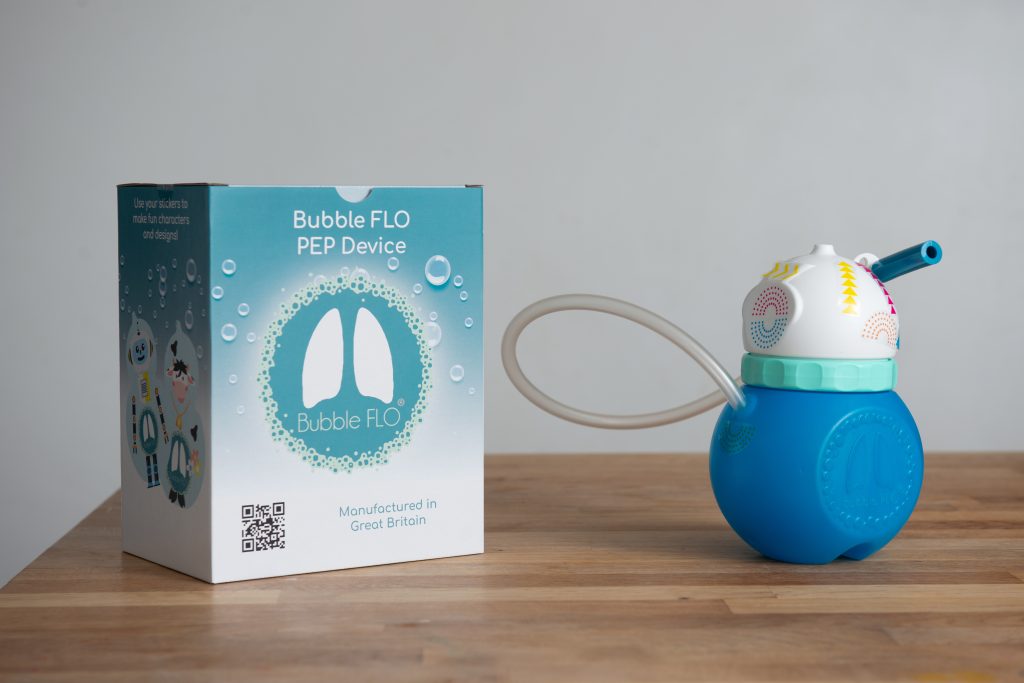

Bubble FLO® has created a fun, child friendly, visually engaging, and effective physiotherapy medical device the Bubble FLO® PEP (Positive Expiratory Pressure) Device for the treatment of chronic lung conditions.

Background

Bubble FLO® was set up by Katie Vance to develop a child friendly, engaging and effective physiotherapy medical device- a Bubble Positive Expiratory Pressure (PEP) Device for the treatment of chronic lung conditions.

Positive-expiratory-pressure (PEP) therapy is a respiratory therapy that applies resistance to expiration, to produce positive airway pressure. Since the 1930s, PEP has been used to improve oxygenation, increase lung volume and reduce venous return in patients with congestive heart failure. PEP improves collateral ventilation, secretion clearance, aerosol distribution and functional residual capacity. (Respiratory Care:April 2009, Vol 54, No.4)

Challenge

The idea of creating a Bubble PEP device evolved when Katie’s daughter was diagnosed with a lifelong respiratory condition and the equipment supplied to carry out vital twice daily physiotherapy was very basic and lacked visual engagement for children. Katie discovered there was no specific Paediatric equipment available, so she decided to develop a Bubble PEP Device which was fun, engaging and effective in clearing secretions from the lungs, and that was aesthetically pleasing, easily portable and easy to empty and re-fill.

The technology did not exist to meet these key practical needs and Katie recognised that such a product could be revolutionary in this critical field. The prototype that she developed was given very positive feedback from physiotherapists who worked with Katie’s daughter, and they expressed a need for a similar device for use by other patients and so Bubble FLO® was born.

Solution

To develop the concept Katie contacted Interface, who, after putting out a search to Scotland’s universities and research institutes, partnered her with Kath Sharp, NHS Team Lead in Paediatric physiotherapy at Glasgow Caledonian University, (who introduced the technique to the West of Scotland and acted as a consultant on the project), and Professor Terence Gourlay, from the University of Strathclyde’s Biomedical Engineering Department, who has extensive experience in the design, development and commercialisation of medical devices.

This collaborative project, funded by a Scottish Funding Council Innovation Voucher, focused on the development of a novel respiratory improvement technology aimed at the paediatric sector, but based on known and well-established approaches. The novelty in the proposed approach is centred around making what can be a tiresome therapy for children, fun and engaging.

The experience the Department of Biomedical Engineering has in the production of laboratory, test-ready prototype devices was applied to the project to produce near clinically deliverable prototypes of the proposed technology which were then successfully tested under laboratory conditions.

Subsequently Bubble FLO® was awarded a By Design Grant from Scottish Enterprise, which allowed the prototype design and ergonomics to be developed further.

Through the support of South of Scotland Enterprise, Bubble FLO® worked with an engineer to develop manufacturing tools, create 40 prototypes and completed bio burden and chemical compatibility testing.

Regulatory work has been completed with the support of CPI and Innovate UK to ensure the product is suitable for use.

BubbleFLO are hoping to start clinical trials with the West of Scotland Innovation Hub at the Royal Hospital for Children in Glasgow soon.

Interface have continued to assist Bubble FLO® brokering collaborations with the University of Strathclyde to create a brand and marketing strategy to target families of children with respiratory conditions and with Edinburgh Napier University to develop a “How to Set Up and Use” animated video with the aim of using animated characters to turn what can be a very daunting experience for a child into a fun and engaging one.

Benefits

As the Bubble FLO® PEP Device will be more engaging for children than the current NHS equipment; children will be much more motivated to carry out effective physiotherapy sessions and, in turn, this has the potential to save the NHS budget considerably through a reduction in hospital admissions for respiratory treatment.

Whilst initially, sales of the Bubble FLO® PEP Device will be to parents online, it is hoped the NHS will purchase this new medical equipment as a long-term investment to reduce their overall budget after completion of an upcoming clinical trial with the West of Scotland Innovation Hub, Royal Hospital for Children in Glasgow.

The development of the proposed technology will underpin the foundation of the commercial activity around this novel product. The company have benefitted from the University’s expertise in the development of prototypes, their laboratory evaluation and expertise in tooling design and production of the medical devices.

Subsequent collaborations have provided Bubble FLO® with a marketing and targeting strategy and produced a novel animated guide for children and parents to be able to use the device at home.

The academic partner has benefitted through this new research activity in the paediatric respiratory sector and in the use of this project as a case study for teaching purposes. In addition, the project fits very well with the Department’s objective of being supportive of the Scottish life science and med tech sectors.

This project was nominated for Innovator of the Year at the Scottish Knowledge Exchange Awards and won a Wild Card at the Scottish EDGE.

This one-day event will showcase impact success stories, offer you a chance to find a partner from another Scottish university, and give you the opportunity to access funds for impact collaborations. Inspirational sessions include a keynote speech from Mark Miodownik and skills development and networking facilitated by Skillfluence.

The IAA Impact Festival is organised by the five Scottish universities with EPSRC Impact Acceleration Accounts (IAAs): University of Edinburgh, University of Strathclyde, University of Glasgow, Heriot-Watt University and University of St Andrews.

Plenary sessions

Our keynote speaker is Mark Miodownik, Professor of Materials and Society at UCL. He champions materials science research that links to the arts and humanities, medicine and society. Mark established the Institute of Making, where he is a director and runs the research programme. He also recently set up the Plastic Waste Innovation Hub to carry out research into solving the environmental catastrophe of plastic waste. Mark is a broadcaster and writer on science and engineering issues, and believes passionately that to engineer is human. In 2018 he was awarded an MBE for services to materials science, engineering and broadcasting.

The keynote will be followed by lightning talks from impact leaders from the five leading Scottish universities in science and engineering. The speakers will share their experiences of creating different types of impact from social and policy impact to industry collaboration, commercialisation and company creation. Learn how our speakers have leveraged the support available to them to further their career and translate their research into impact. The speakers are:

- Larissa Naylor, University of Glasgow

- Dan Hodgson, University of Edinburgh, The Physics of Goo: Impact from soft matter and complex fluids

- Laura Wicks, Heriot-Watt University, Lothian Lugs – flipped the model of university engagement

- Charles McLeod, University of Strathclyde, Innovation to impact: Enhancing through-life asset management, from cradle to grave

- Ross Gillanders, University of St Andrews

- Networking sessions

- Skillfluence will facilitate structured networking that will allow you to meet other researchers from across Scotland and creatively explore opportunities to collaborate.

Interface will be exhibiting at this event so come and join us.

Background

Ecomar Propulsion Ltd is based in Fareham on the South Coast of the UK and was first registered in 2019. Ecomar Propulsion Ltd is involved in the research, development and production of high performance electric and hybrid hydrogen marine propulsion systems.

Their team of highly skilled engineers and technical experts are working to reduce global emissions by creating high efficiency, high output marine engines and energy storage solutions. The company only works with fully clean electric systems to allow current vessel owners the opportunity to seamlessly transfer to clean marine or new build yards to offer electric vessel options.

Ecomar Propulsion produces two products for clean marine vessels; outboard systems and inboard systems powered by battery and hydrogen with a company aspiration of removing 10 million tonnes of toxic exhaust fumes from the marine environment within 10 years.

In 2021 the company increased its workforce to 8 staff and then to 12 by Jan 2023, with further expected growth. The company has been recognized with several awards from the Maritime UK (Solent) Clean Marine Innovator and Maritime UK Diversity Champion Finalist 2022 through to SETSquared University Network Award for Environmental Impact 2022.

The Challenge

The business challenge for Ecomar Propulsion arose when their manufacturer of hydraulic rams in the Far East ceased supply of their products. This left a significant challenge for Ecomar Propulsion but also an opportunity for the company to look at developing their supply chain within the UK. Another requirement was to ensure the materials being used are as environmentally sustainable as possible from a circular economy perspective.

The Solution

Scottish Enterprise introduced Ecomar Propulsion to NMIS, and as a result of their interest in developing a Scottish supply chain and bringing production to Scotland to overcome a global supply chain issue of electric outboard motors, they were eligible to apply for the Inward Investment Catalyst Fund to support activity. The Inward Investment Catalyst Fund supports businesses not yet located in Scotland but seeking to establish stronger ties with academia here. As well as funding the research and development it provides an opportunity for the company to establish relationships and give insight into other aspects of the Scottish landscape, such as further investment opportunities, supply chains and the skills base to strengthen the case for investing in Scotland.

The teams at NMIS and University of Strathclyde developed their understanding of the design and manufacturing parameters to find replacement components that would be robust enough for the extreme demands of the marine environment. Research and outreach were carried out with companies specializing in hydraulic production in Scotland. Further discussions with selected companies are taking place to develop future alternatives to current suppliers in order to close the gap in the market and provide consistency of supply.

The Next Steps

This project has allowed Ecomar Propulsion to better understand the work of NMIS and the University of Strathclyde and how the skills of the teams can allow Ecomar to plan further growth in Scotland and engage with the wider available supply chain.

Whilst an immediate supplier for marine hydraulic rams was not found, the team have introduced Ecomar Propulsion to several companies which they would not have met had they not taken part in this project. Through meeting senior members of the academic community, potential further opportunities have been identified to explore additional supply chain introductions and manufacturing routes in Scotland for Ecomar Propulsion’s full product range.

Continued collaboration will be facilitated with the Head of Electrification Manufacturing Programmes at NMIS, and allow Ecomar Propulsion and NMIS to engage with Scottish Government and Scottish Enterprise in relation to future facility planning and supply chain partnerships. Additionally, opportunities will be aligned with the University of Strathclyde’s strategic direction in electrification manufacturing, notably in PEMD (power electronics, machines and drives) through DER-IC Scotland (Driving the Electric Revolution Industrialisation Centre), ensuring that expansion of capabilities is informed and driven by industry requirements.

This project benefitted from the Scottish Inward Investment Catalyst Fund. The Scottish Inward Investment Catalyst Fund launched by Interface and the Scottish Government promotes Scotland as a leading destination for inward investment and supports businesses not yet located in Scotland but seeking to establish stronger ties with academia here. As well as funding research and development it provides an opportunity for the company to establish relationships and give insight into other aspects of the Scottish landscape, such as further investment opportunities, supply chains and the skills base to strengthen the case for investing in Scotland.

Learn more about the Scottish Inward Investment Fund